We're here to assist you with any questions, concerns, or inquiries you may have.

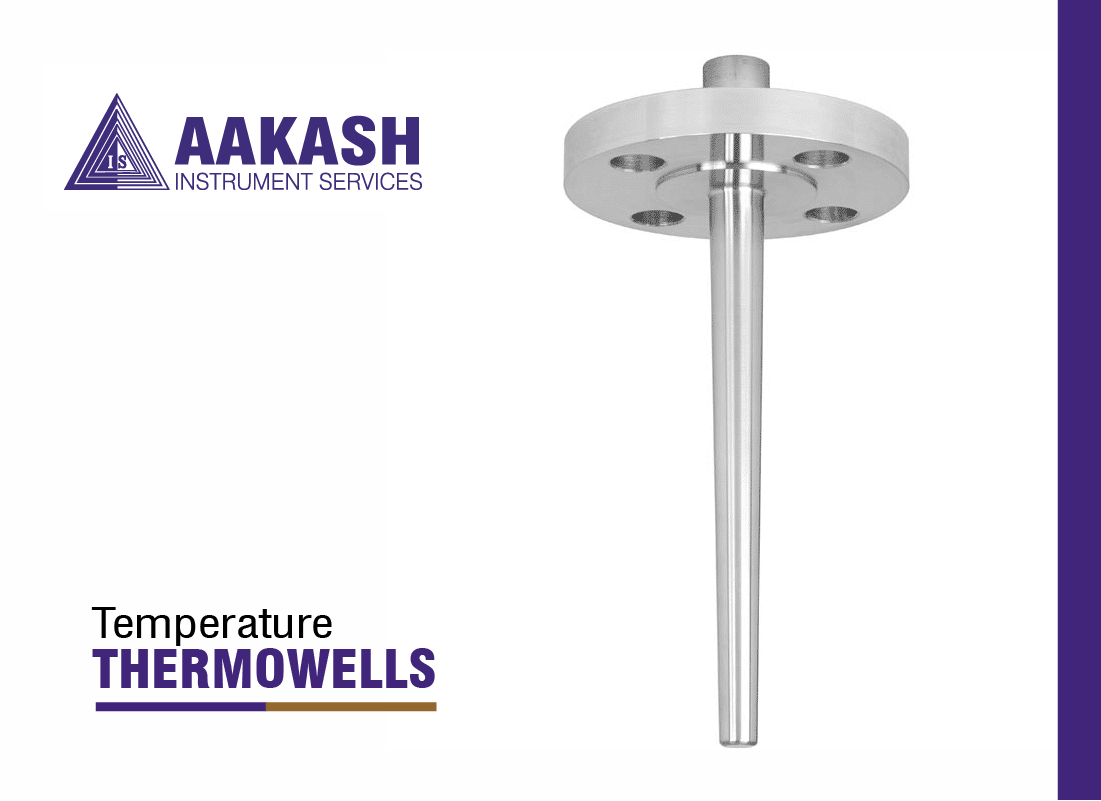

Thermowells serve as protective structures for temperature sensors like thermocouples, thermistors, and bimetal thermometers. They shield these sensors from potential harm caused by excessive pressure, material velocity, and corrosion. Additionally, thermowells enhance the lifespan of the sensors, enable easy replacement without system drainage, and minimize the risk of contamination. In high-pressure scenarios, thermowells are usually machined from bar stock to ensure their integrity. Conversely, smaller thermowells for low-pressure environments can be made from tubing, with one end welded shut.

1. Essential for protecting temperature sensors from harsh industrial environments.2. Construction material: Typically corrosion-resistant, ensuring longevity and durability.3. Design options: Designed with different insertion lengths and diameters for specific temperature sensor requirements.4.Process connections: Threaded, flanged, or welded, catering to diverse installation needs.5. Crucial for accurate and reliable temperature measurement in industrial processes.

1. Provided with drilled solid tip.2. Weld procedure and qualifications available upon request.3. Can be supplied with lagging extensions.4. Two spanner flats milled if hex bar material unavailable5. Plug and chain options available.6. Maximum length for machined thermowells is 1200mm.

There are various types of thermowells, including threaded, socket-weld, and flanged. Threaded thermowells have threads and are easy to install and remove, but are not suitable for high-pressure applications. Socket-weld thermowells are sturdier and more durable but more expensive, but only suitable for certain socket weld fittings. Flanged thermowells have flange collars connected to mating flanges and are strong but expensive. They are generally used in high-pressure applications where threaded or socket weld thermowells aren't suitable.