We're here to assist you with any questions, concerns, or inquiries you may have.

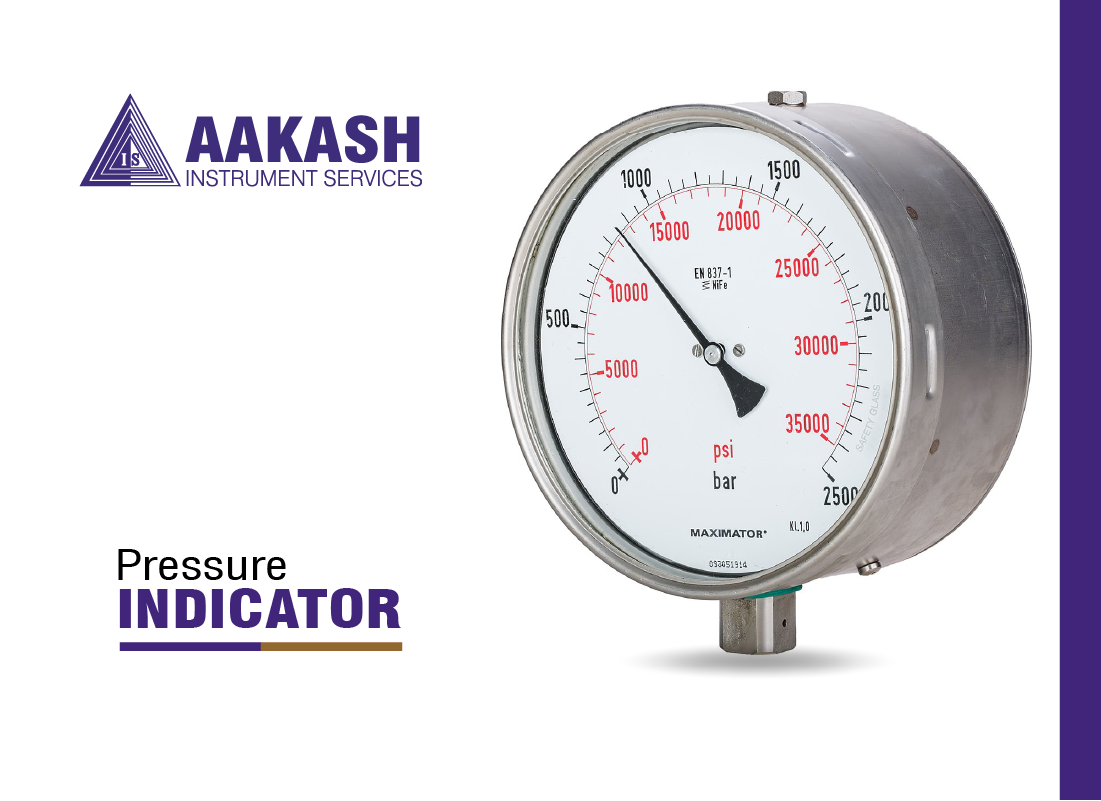

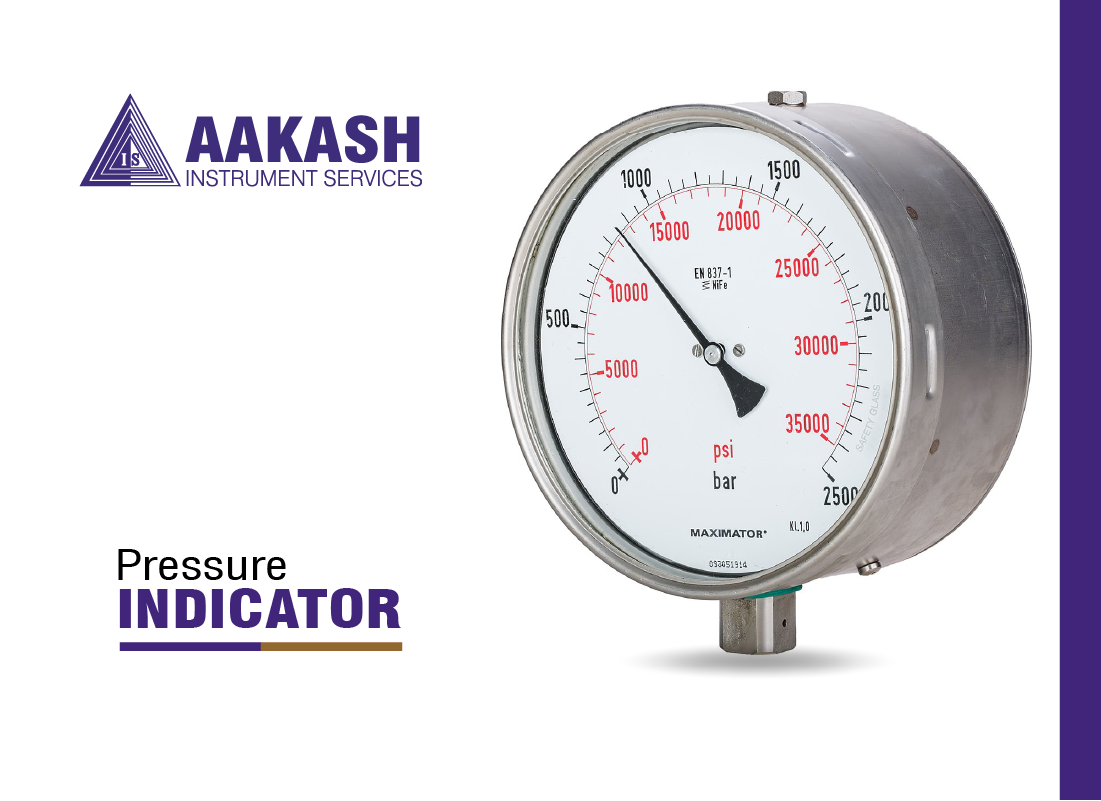

Pressure indicators are a type of instrumentation designed for measuring low pressure in self-contained systems. They are well-suited for various applications including room monitoring, HVAC systems, and testing the performance of pumps or pneumatic controls and regulators.

1. Measures and displays pressure of gases or liquids in various systems.2. Features a pressure range in units like psi, bar, or kPa.3. Display types range from analog dials to digital numerical or graphical displays.4. Accuracy measures the smallest increment of pressure displayed.5. Offers units of measurement flexibility, pressure connection types, seals for media compatibility, and operational temperature ranges.6. Complies with power sources, mounting options, and environmental protection ratings like IP.7. Suitable for various installation and usage scenarios, from industrial processes to laboratory settings.

1. Pressure range: Defines minimum and maximum pressures in units like psi, bar, or kPa.2. Accuracy: Measures pressure as a percentage of the full-scale reading.3. Resolution: Determines the smallest increment the indicator can display.4. Display types: Analog dials, digital numerical displays, or graphical interfaces.5. Units of measurement flexibility: Allows adaptation to specific application requirements.6. Pressure connection: Specifies how the indicator interfaces with the measured system.7. Pressure seals: Ensures compatibility with diverse media and prevents leaks.8. Operating temperature ranges: Defines environmental limits for reliable performance.9. Additional features: Data logging, alarms, and communication protocol compatibility.

Pressure indicators are essential in various industries for monitoring and controlling pressure levels. Common types include Bourdon tube gauges, digital pressure gauges, manometers, and vacuum gauges. These indicators help maintain safety, efficiency, and operational excellence by accurately measuring gas pressure, liquid pressure, and negative pressure levels. They ensure pressure levels are monitored and controlled within specified limits, ensuring safety and efficiency.